Strong Arguments

Proven quality from BB- Umwelttechnik

During development, we were able to fully utilise our extensive knowledge and many years of experience with this technology. You can expect a machine at the highest level.

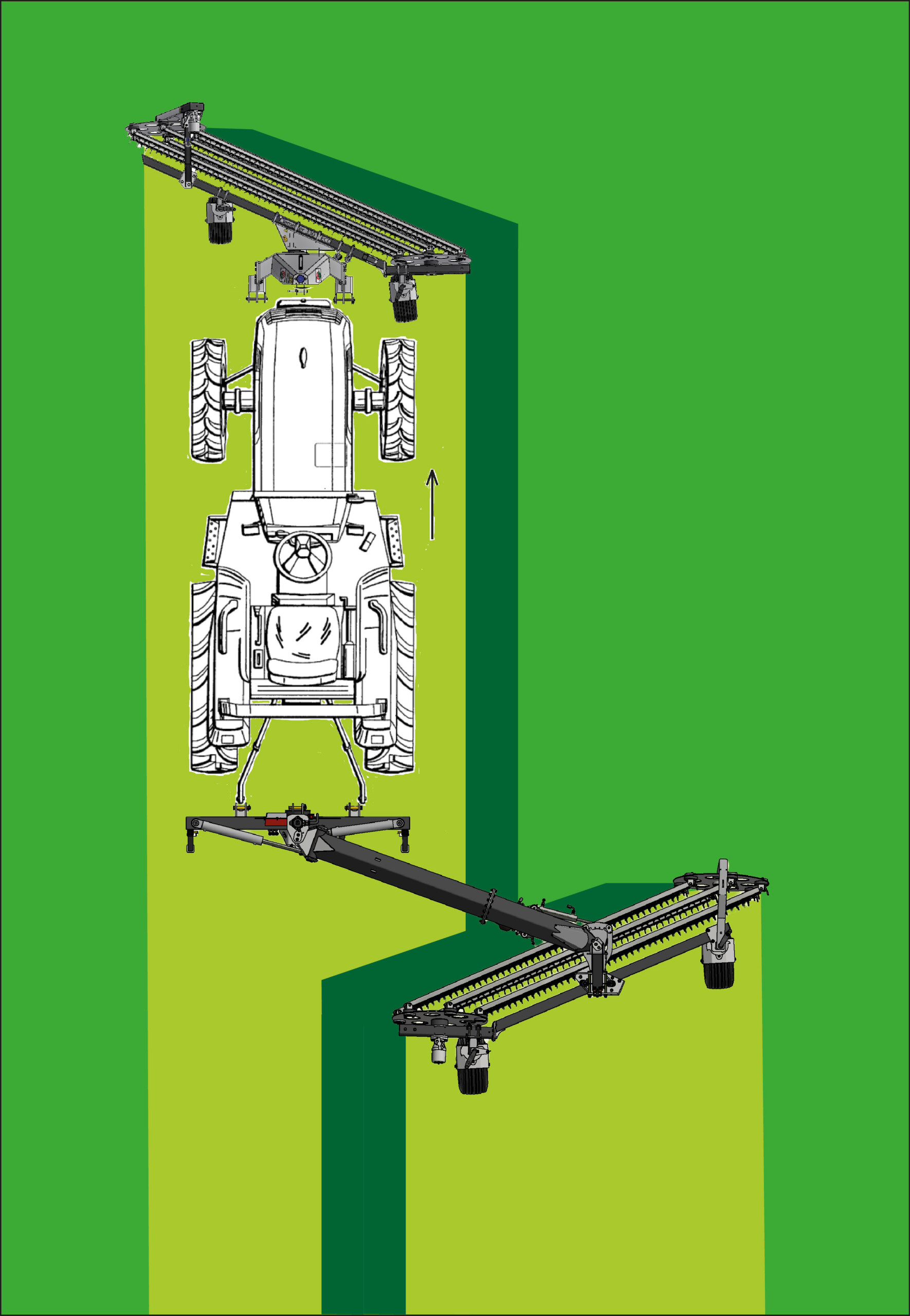

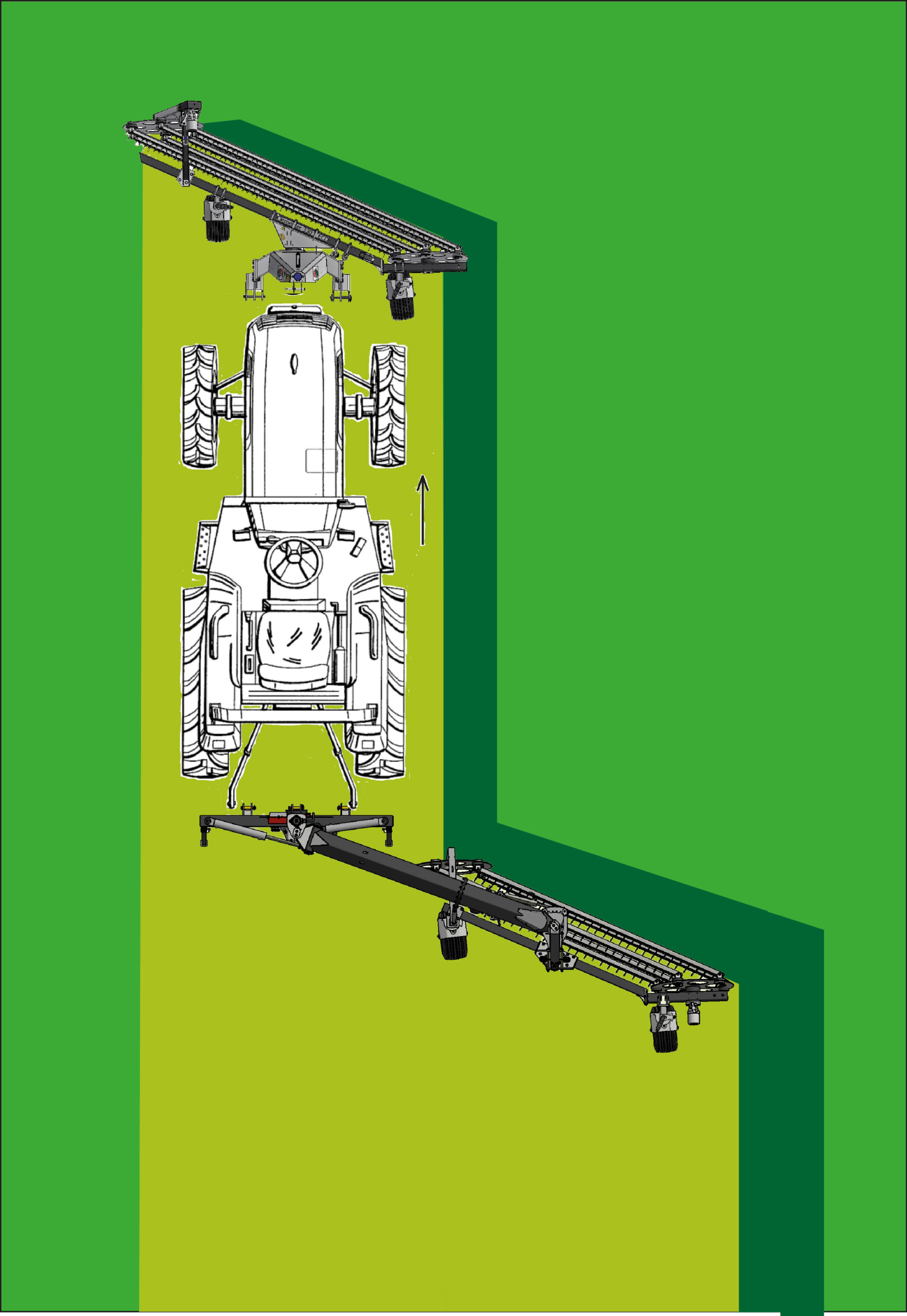

Maximum soil levelling

The optimum weight distribution with a front-rear combination enables operation with a small carrier vehicle. Hydraulic relief of the swath drum, fitted as standard, improves driving comfort and minimises drifting on slopes.

Uncomplicated swathing

Swathing under trees, along ditches or embankments is child’s play thanks to the swathing drum being offset to the side of the carrier vehicle. The carrier vehicle is further away from obstacles.

Solid drive

The swath drum is driven by its own oil supply with PTO drive. The standard overload protection protects against damage.

Perfect research result

A pendulum mount on the swath drum enables optimum ground tracking. In addition, infinitely adjustable feeler wheels ensure a perfect cultivation result

Convenient operation

The respective function can be easily selected via a control panel. Only one DW control unit with floating position and a 3-pin socket are required to control all functions.

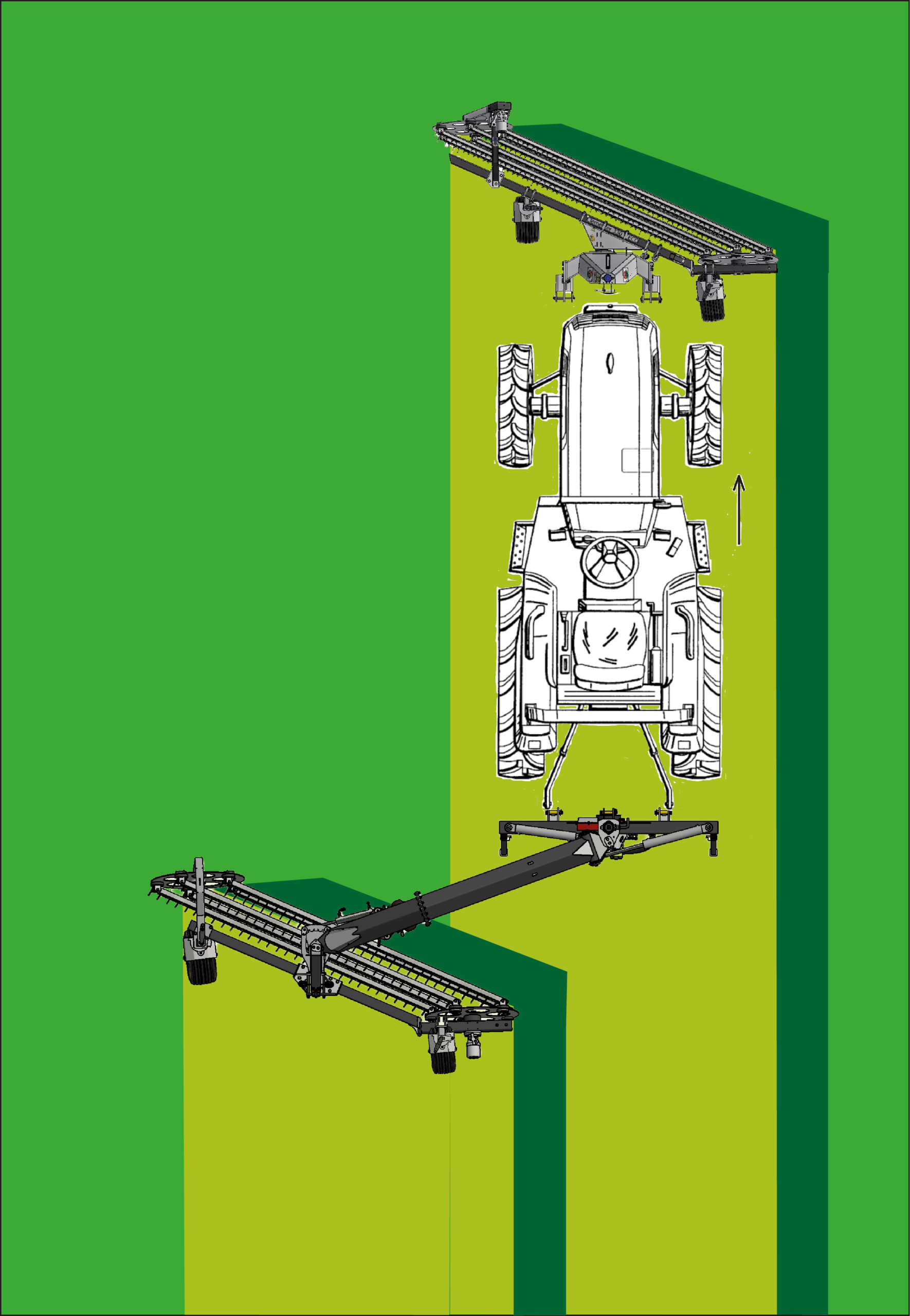

Safe transport

Automatic stopping of the swivel arm in the transport position prevents operating errors during road transport. Driving comfort is excellent thanks to vibration damping.

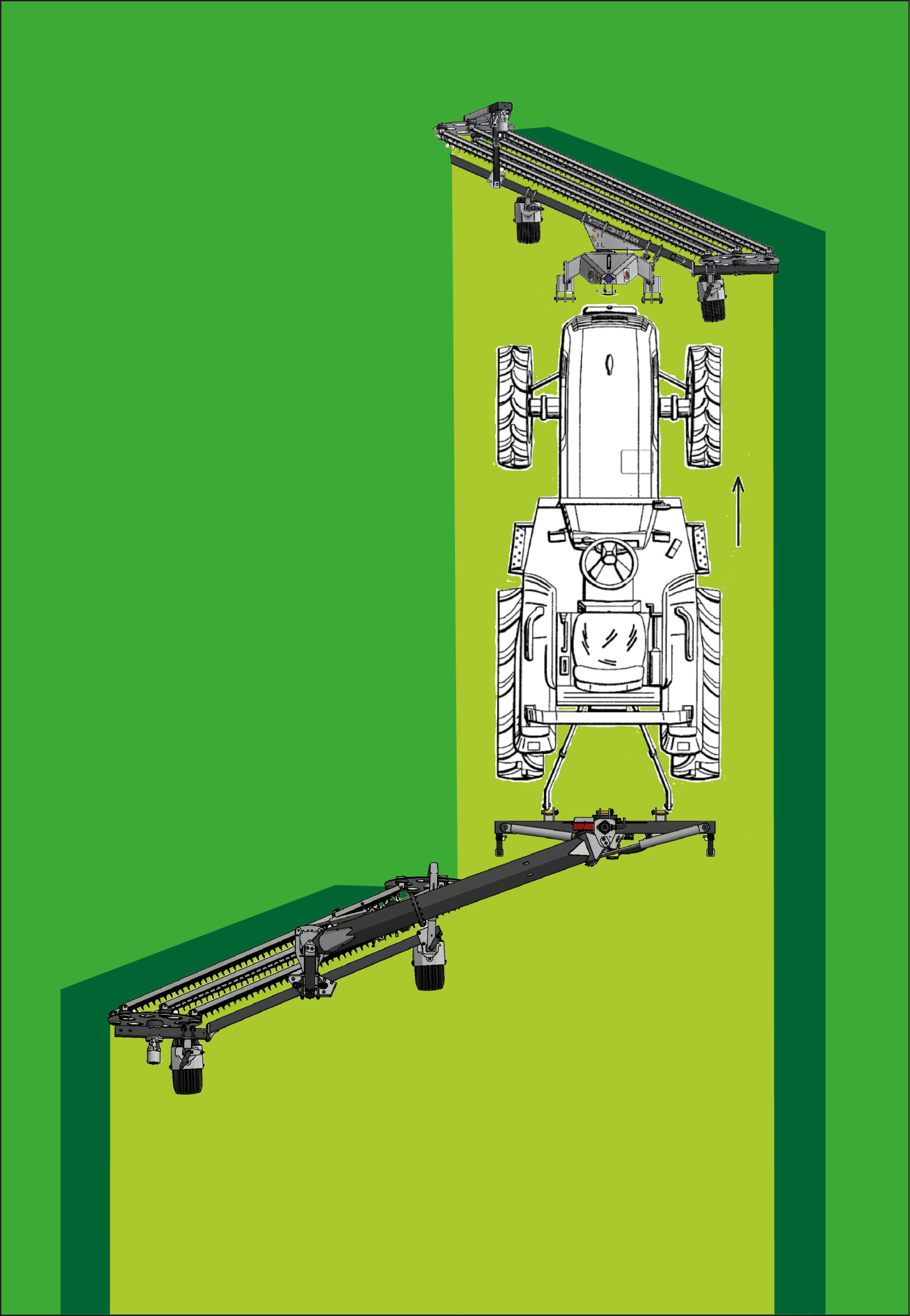

Two variants for maximum flexibility

With two variants of the rear rake, we can realise all desirable combinations. A distinction is made as to whether the swath is deposited on the left or right.

Rear side rake left

Centre swath

Combination: One-piece front rake + rear rake left

Swivelling direction: “Right”

Result: Medium swath

Advantage: The entire forage is lifted from the ground once (absolutely unique selling point for centre swaths)

Double swath

Kombination: Einteiliger Frontschwader + Heckschwader links

Schwenkrichtung: “LINKS”

Ergebnis: Doppelschwad

Vorteil: Doppelschwad ohne Überfahren des Futters mit kleinem Trägerfahrzeug möglich

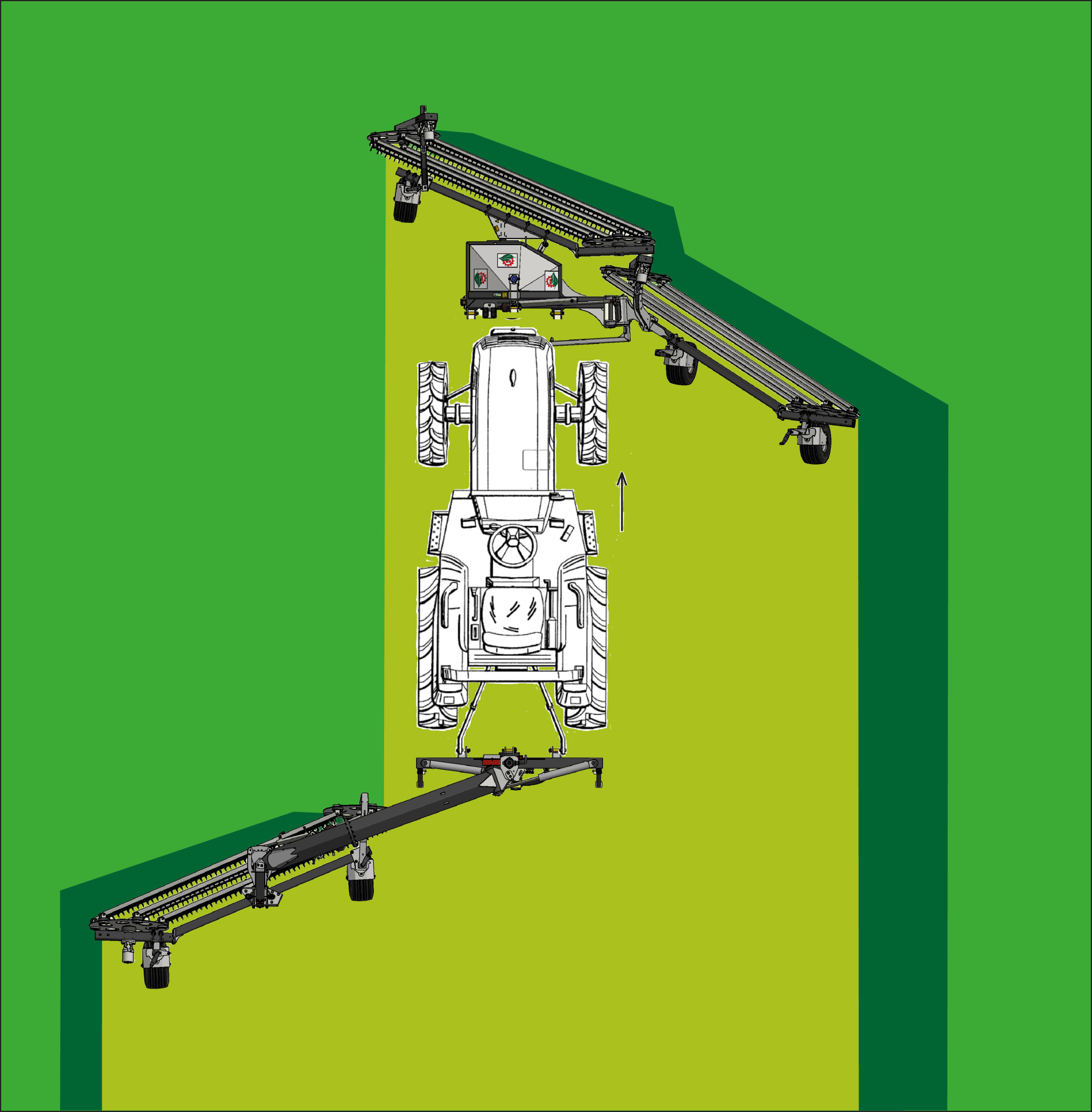

Triple swath

Combination: Two-piece front rake + rear rake left

Swivelling direction: “Left”

Result: Triple swath

Advantage: Enormous area coverage

Rear side rake right

Double swath

Combination: One-piece front rake + rear rake on the right

Swivelling direction: “Right””

Result: Double swath

Advantage: Double swath possible without driving over the forage with a small carrier vehicle

Night swath

Combination: One-piece front rake + rear rake on the right

Swivelling direction: “Left”

Result: Night swath

Advantage: All the food is picked up once from the floor

Standard equipment

New: With hydraulic swath cloth as standard

Electro-hydraulic control

Swath drum drive via rear PTO shaft with its own independent oil supply and overload protection

Optimum ground tracking thanks to pendulum mounting on the swath drum and infinitely height-adjustable feeler wheels

Hydraulic relief of the swath drum

Hub drive (=direct drive)

Wind protection, minimises the throwing over of fodder in headwinds and thus also prevents clogging of the radiator grille of the carrier vehicle

Overthrow guard Mounted on the right swath drum, prevents the forage from being pulled up, especially with heavy forage

Three-point hitch KAT 1 + 2

All parts powder-coated and galvanised

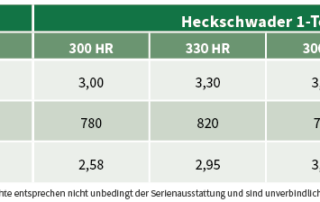

Working widths of 3.0 and 3.3 metres

Equipment options

Walterscheid cardan shaft (l=600 mm)

Different tine spacings can be selected

Hay 6 model: 6 tine carriers + 80mm tine spacing for hay and wilted silage

Silage 6 model: 6 tine carriers + 50 mm tine spacing for very heavy forage (arable forage)