Advantages of the system

Simple operation: Place the knife (magnetic holder, any position in the longitudinal axis) and press the start button.

Fully automatic: After pressing the start button, the machine works completely independently and switches off automatically when the knife is finished sharpening. You can use your valuable time elsewhere.

- Flexible: Any knife length can be ground (max. 3.35 m knife without repositioning)

Wide range of adjustment possibilities: Almost all types of mower blades can be grinded.

Well-designed: The grinding intensity can be easily adjusted with a simple rotary button.

Each blade is grinded individually: The stock removal is the same on every blade, i.e. regardless of whether it is a new blade or an old blade, only as much as necessary is grinded down.

Special grinding wheel: No heat generation during the grinding process, therefore no structural changes or loss of hardness on the blade.

Precisely adjustable cutting edge angle: The result is an edge that is in no way inferior to the grind of a new blade.

The sense of achievement: Minimal power required for mowing and very long service life.

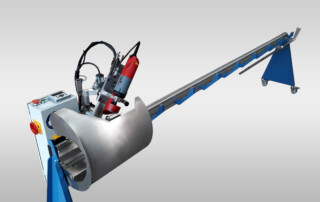

Model SG-22/4000 for knives up to 3.35 meters long

Optional extension rail for wall mounting: additional length of 4 m; thus e.g. two knives can be ground in one setup.

Optional dust basket catches up to 80 % of the grinding dust; removable with one handle.

Advantages of the system

Motor with reversal of rotation direction, each blade side is ground from bottom to top

Made from industrial components

Manual placing of the knife on magnetic holder (adjustable)

Automatic grinding machine switches off automatically after completion of the grinding process

Manual operation possible

Each blade is grinded individually: The stock removal is the same on every blade, i.e. regardless of whether it is a new blade or an old blade, only as much as necessary is grinded down.

Advantages of the system

The blade is clamped in a fixed position. The grinding and longitudinal movements are carried out via the angle grinder, thus approx. 50 % faster compared to conventional hand-guided devices, as the clamping and unclamping of the mower blade is eliminated when changing from blade to blade.

Very good handling due to rotary wheel as positioning aid.

Clearance-free guide rails ensure precise and smooth movement of the angle grinder.

Wide range of adjustment possibilities: All types of mower blades can be grinded.

Robust construction

High quality components

All components are screwed. This avoids distortion due to welding. Also the exchangeability or upgradeability is much easier due to screw connections.

Includes high-quality, variable-speed angle grinder from Metabo, 1000 watts, 125 mm wheel diameter, with electronic control, soft start and overload protection.

Maximum sharpenable double knife length without reclamping (depending on the Messerfix type):

– 2.40 meters

– 3.10 meters

– 3.35 metersThe sense of achievement: Minimum power required for mowing and very long service life.